Showing 25–36 of 299 results

-

10kg Potato Peeler Machine

Upgrade your kitchen operations with our 10Kg Potato Peeler Machine, engineered for efficiency, speed, and hygiene. Perfect for restaurants, catering businesses, hotels, and commercial kitchens, this machine peels large batches of potatoes effortlessly—saving both time and labor. Built with a robust stainless-steel body and powerful motor, it ensures smooth performance and long-lasting durability.

The Platinum Flour Mill 10Kg Potato Peeler Machine is a reliable workhorse for medium to large-scale food operations. With a high-performance motor and abrasive-coated drum, it quickly removes potato skins with minimal wastage. Its user-friendly design includes a secure locking lid, side discharge outlet, and water spray inlet for continuous rinsing during peeling.

Constructed from premium stainless steel, the machine resists rust and corrosion, making it suitable for daily commercial use. Cleaning is quick and easy thanks to its openable drum and minimal crevices. Whether you’re preparing for a busy lunch service or bulk food prep, this machine delivers consistent results every time.

Key Features

- 10 Kg Capacity – Handles larger batches, ideal for commercial food preparation.

- Rugged Stainless Steel Body – Ensures long-lasting durability and easy cleaning.

- Efficient Abrasive Peeling Drum – Peels uniformly while preserving potato quality.

- High-Speed Motor – Provides consistent performance with smooth operation.

- Water Outlet System – Ensures clean washing and peeling simultaneously.

- Compact & Sturdy Design – Occupies minimal space while offering maximum output.

- Transparent Top Lid – Allows safe and easy monitoring during operation.

- Easy to Operate & Maintain – Designed for user convenience and longevity.

Ideal Applications

- Large Restaurants & Hotels

- Food Canteens & Industrial Kitchens

- Catering & Event Kitchens

- Chips and Snack Manufacturers

- Food Processing Units

Why Choose the Platinum Flour Mill 10Kg Potato Peeler Machine?

The 10Kg Potato Peeler Machine is the perfect choice for businesses that require bulk potato peeling with precision and consistency. Its heavy-duty motor and stainless steel construction make it capable of handling tough commercial demands while maintaining hygiene and safety standards.

Whether you’re preparing potatoes for chips, curries, or mass cooking, this machine ensures fast, uniform, and effortless peeling. With minimal maintenance and high output efficiency, it’s an indispensable tool for any professional food establishment aiming to save time and enhance productivity.

-

10×16 Electric Pizza Oven

The Platinum Flour Mill 10×16 Electric Pizza Oven is a high-performance baking machine designed for restaurants, cafes, bakeries, and home chefs who want perfectly baked pizzas every time. Though compact in size, this oven delivers the same performance and quality as a commercial Gas Pizza Oven, providing consistent heat distribution for crispy crusts and evenly cooked toppings.

Made from premium stainless steel, it ensures durability, hygiene, and easy maintenance. Its electric-powered heating system offers precise temperature control, making it ideal for pizzas, bread, sandwiches, cookies, and other baked dishes. Whether for commercial or home use, this oven guarantees professional results with energy efficiency.

Key Features

- Compact 10×16 Baking Chamber – Perfect for small to medium pizzas and quick bakes.

- Electric Heating System – Provides uniform heat similar to a traditional Gas Pizza Oven.

- Durable Stainless Steel Construction – Ensures hygiene, rust resistance, and long life.

- Even Temperature Distribution – Prevents uneven cooking and delivers consistent results.

- Adjustable Temperature Control – Perfect for different baking needs.

- Glass Viewing Window – Allows easy monitoring of your food while it bakes.

- Energy Efficient – Designed to reduce power consumption without compromising performance.

- Easy to Use & Clean – User-friendly controls and smooth surfaces simplify operation.

Why Choose the Platinum Flour Mill 10×16 Electric Pizza Oven?

The Platinum Flour Mill 10×16 Electric Pizza Oven combines modern electric technology with the performance of a professional Gas Pizza Oven. Its compact size, consistent heat output, and energy-efficient design make it a top choice for those seeking quality baking in limited spaces.

This oven is perfect for both commercial and home kitchens, offering crisp, golden pizzas and evenly baked breads every time. If you’re looking for a durable, reliable, and easy-to-use pizza oven, this is the perfect match.

-

10×16 Gas Pizza Oven

The Platinum Flour Mill 10×16 Gas Pizza Oven is a high-performance, compact, and energy-efficient baking solution designed for restaurants, cafés, pizza outlets, and commercial kitchens. Built to deliver authentic, crispy, and evenly baked pizzas, this oven combines powerful gas heating with precise temperature control, ensuring consistent quality with every bake.

Crafted from high-grade stainless steel, the oven offers durability, hygiene, and easy maintenance, while its compact size makes it perfect for kitchens with limited space. Whether you’re baking pizzas, garlic bread, sandwiches, or bakery snacks, this gas pizza oven delivers fast, reliable, and professional results.

Key Features

- Compact 10×16 Baking Chamber – Perfect for small and medium-sized pizzas.

- Efficient Gas Heating System – Ensures quick preheating and even heat distribution.

- Durable Stainless Steel Construction – Rust-resistant, hygienic, and built for long-term use.

- Adjustable Temperature Control – Allows precise heat adjustment for perfect baking.

- Heat-Resistant Glass Window – Enables easy viewing during the baking process.

- Energy Efficient – Consumes less fuel while delivering maximum performance.

- Easy Operation & Cleaning – Simple controls and smooth surfaces for user convenience.

Ideal Applications

- Pizza Outlets & Restaurants

- Cafés & Bakeries

- Food Trucks & Fast Food Counters

- Commercial & Cloud Kitchens

- Catering Businesses

Why Choose the Platinum Flour Mill 10×16 Gas Pizza Oven?

The Platinum Flour Mill 10×16 Gas Pizza Oven is the perfect combination of compact design, superior performance, and fuel efficiency. Designed for professionals who demand quality and speed, it delivers crispy, evenly baked pizzas every time. Its stainless steel body, adjustable temperature control, and powerful gas heating make it a dependable choice for any commercial food operation.

Whether you’re running a pizza outlet, cafe, or catering business, this Gas Pizza Oven ensures consistent baking performance and authentic results that your customers will love.

-

12 Inch Vertical Flour Mill

The Platinum Flour Mill 12 Inch Vertical Flour Mill is a durable and high-performance machine designed to meet the daily flour grinding needs of small to medium-scale businesses. Whether it’s wheat, rice, maize, besan, or millet, this flour mill ensures uniform texture, fine quality output, and long-lasting reliability.

Equipped with premium emery stones and a heavy-duty cast-iron body, this model is built to handle continuous operation with minimal maintenance. It’s perfect for flour mills, grocery stores, hotels, and small food industries looking for fresh and pure flour production every day.

Key Features:

- High Grinding Efficiency: Capable of processing large quantities with uniform results.

- Premium Quality Emery Stones: Ensures smooth grinding and fine flour texture.

- Robust Construction: Built with strong cast iron for long life and stability.

- Energy Efficient: Designed to save power without compromising performance.

- Easy Operation: Simple controls for quick setup and user-friendly handling.

Why Choose the Platinum Flour Mill 12 Inch Vertical Flour Mill?

The Platinum Flour Mill 12 Inch Vertical Flour Mill strikes the perfect balance between power and performance. It’s designed to deliver high output capacity while maintaining consistent flour quality. Whether you’re running a small flour business or need a reliable grinder for daily use, this machine ensures durability, economy, and efficiency.

With its rugged build and superior grinding mechanism, it’s a dependable choice for users who value quality, hygiene, and productivity.

-

12 Mm Bread Slicer Machine

The Platinum Flour Mill 12 mm Bread Slicer Machine is designed to deliver uniform, clean, and professional bread slices with ease and efficiency. Perfect for bakeries, hotels, cafés, restaurants, and food production units, this machine ensures a consistent slicing thickness of 12 mm, ideal for toast, sandwiches, and packaging-ready loaves.

Built with high-quality stainless steel blades and a durable frame, it guarantees smooth operation and long-lasting performance. The compact, easy-to-use design makes it suitable for both small and large-scale bakery operations that prioritize accuracy, hygiene, and productivity.

Key Features

- 12 mm Slice Thickness – Provides uniform and consistent slices every time.

- High-Quality Stainless Steel Blades – Sharp, rust-resistant, and designed for precise cutting.

- Heavy-Duty Construction – Ensures stability, durability, and long operational life.

- Fast & Efficient Performance – Slices bread loaves quickly with clean, smooth cuts.

- User-Friendly Design – Easy to operate, maintain, and clean.

- Compact & Space-Saving – Fits seamlessly in bakery counters or kitchen workspaces.

- Hygienic Operation – Designed to meet food safety standards with easy-to-clean parts.

Ideal Applications

- Bakeries & Bread Factories

- Restaurants & Hotels

- Café and Sandwich Shops

- Commercial Food Production Units

- Supermarkets & Packaging Units

Why Choose the Platinum Flour Mill 12 mm Bread Slicer Machine?

The Platinum Flour Mill 12 mm Bread Slicer Machine is the perfect choice for bakeries and food businesses that demand precision, speed, and hygiene. With its robust design, sharp blades, and user-friendly operation, it delivers uniform bread slices every time, helping you save time while maintaining product consistency and presentation quality.

-

12×18 Electric Pizza Oven

The Platinum Flour Mill 12×18 Electric Pizza Oven is a compact and efficient solution for small restaurants, cafes, food stalls, and home-based kitchens that need fast and consistent baking. Its electric heating elements provide steady, even heat across the chamber, ensuring perfectly baked pizzas, garlic bread, sandwiches, and other baked snacks. Despite its small footprint, it delivers impressive performance, making it ideal for quick-service food environments.

Built with a sturdy, heat-resistant body and simple temperature controls, the 12×18 Electric Pizza Oven is easy to operate and maintain. It heats up quickly, saves energy, and delivers dependable results batch after batch. Whether you’re upgrading your kitchen setup or starting a new food venture, this oven offers excellent durability, smooth operation, and professional-quality baking in a space-saving design.

Key Features

- Spacious 12×18 Baking Chamber – Suitable for medium pizzas or multiple small items.

- Advanced Electric Heating System – Delivers even heat, comparable to a Gas Pizza Oven.

- Stainless Steel Construction – Rust-free, hygienic, and built for long-term durability.

- Uniform Heat Circulation – Ensures evenly baked pizzas and snacks every time.

- Adjustable Temperature Control – Perfect for different recipes and baking requirements.

- Glass Viewing Window – Allows easy monitoring during baking.

- Compact & Space-Saving Design – Fits neatly into any professional or home kitchen.

- Energy Efficient – Optimized to consume less electricity while maintaining high output.

Why Choose the Platinum Flour Mill 12×18 Electric Pizza Oven?

The Platinum Flour Mill 12×18 Electric Pizza Oven combines the convenience of electricity with the baking power of a Gas Pizza Oven, giving you professional-level results without the need for gas connections. It’s perfect for businesses and home bakers looking for speed, precision, and efficiency in every batch.

This oven ensures consistent temperature, faster heating, and long-term reliability, making it a smart investment for modern kitchens that want quality, performance, and simplicity in one appliance.

-

12×18 Gas Pizza Oven

The Platinum Flour Mill 12×18 Gas Pizza Oven is a durable, efficient, and high-performance oven designed for restaurants, cafés, bakeries, and food outlets that need consistent, high-quality baking. With its gas-powered heating system, this oven delivers authentic, crispy pizzas with perfectly baked bases and golden toppings—every time.

Built from premium stainless steel, the oven ensures long-lasting durability, hygiene, and easy cleaning. Its compact 12×18 chamber size makes it ideal for small and medium kitchens, while the uniform heat distribution guarantees fast, even baking. Perfect not only for pizzas but also for garlic bread, sandwiches, cookies, and bakery items, this Gas Pizza Oven is an essential addition to any commercial setup.

Key Features

- 12×18 Baking Chamber – Perfect for medium-sized pizzas and multiple bakery items.

- Efficient Gas Heating – Provides quick preheating and consistent temperature control.

- Durable Stainless Steel Body – Ensures hygiene, rust resistance, and long-lasting use.

- Even Heat Distribution – Guarantees perfectly baked pizzas with crispy crusts and soft centers.

- Adjustable Temperature Control – Allows precision cooking for various dishes.

- Glass Viewing Window – Enables easy monitoring while baking.

- Energy Efficient Design – Optimized to save gas without compromising performance.

- Compact & User-Friendly – Ideal for commercial kitchens with limited space.

Ideal Applications

- Pizza Outlets & Restaurants

- Cafés & Bakeries

- Hotels & Catering Kitchens

- Food Trucks & Cloud Kitchens

- Fast Food Counters

Why Choose the Platinum Flour Mill 12×18 Gas Pizza Oven?

The Platinum Flour Mill 12×18 Gas Pizza Oven is a perfect blend of performance, efficiency, and reliability. Its gas heating system, compact design, and precise temperature control make it ideal for commercial kitchens that demand speed and consistency.

Whether you’re baking pizzas, toasting sandwiches, or preparing bakery snacks, this Gas Pizza Oven ensures crispy, evenly cooked results every time — making it an excellent investment for restaurants, cafés, and professional bakers.

-

14 Inch Vertical Flour Mill

The Platinum Flour Mill 14 Inch Vertical Flour Mill is a powerful and efficient grinding solution for commercial and semi-industrial use. Designed to produce fine, fresh, and uniform flour, this model is ideal for grinding a wide variety of grains like wheat, maize, rice, millet, and besan.

Built with premium emery grinding stones and a heavy-duty cast-iron body, this flour mill offers long service life, low maintenance, and consistent output even under continuous operation. Its superior design ensures smooth operation, energy efficiency, and perfect grinding results every time.

Key Features:

- Powerful Performance: High-capacity motor ensures faster and smoother grinding.

- Premium Emery Stones: Delivers consistent texture and fine-quality flour.

- Durable Construction: Robust cast-iron build guarantees long-term durability.

- Energy Efficient: Engineered to save power during prolonged usage.

- Multi-Grain Use: Suitable for grinding wheat, rice, corn, besan, and other grains.

- Low Maintenance: Simple design for easy operation and cleaning.

Why Choose the Platinum Flour Mill 14 Inch Vertical Flour Mill?

The Platinum Flour Mill 14 Inch Vertical Flour Mill is built for businesses that demand speed, strength, and quality. It’s a perfect combination of traditional grinding methods and modern engineering, ensuring purity, precision, and performance in every batch.

Whether you run a flour mill, grocery shop, or small food processing unit, this machine is your reliable partner for producing fresh, nutritious, and high-grade flour efficiently.

Built to last and designed for efficiency — this model is the ideal choice for professional flour makers and food entrepreneurs.

-

14 Liter Mixer Grinder (Tilting Model)

The Platinum Flour Mill 14 Liter Mixer Grinder Tilting Model is a high-performance, durable, and commercial-grade appliance designed for large-scale food preparation. Built with a powerful motor and a 14 Liter stainless steel jar, this machine ensures smooth, efficient, and uniform grinding, mixing, and blending, making it ideal for restaurants, hotels, catering units, industrial kitchens, and food processing centers.

Its innovative tilting design allows for easy pouring and cleaning, reducing manual effort and ensuring maximum hygiene in busy kitchen environments. Whether you’re grinding spices, making gravies, chutneys, or thick batters, this tilting mixer grinder provides speed, precision, and durability in every operation.

Key Features

- 14 Liter Stainless Steel Jar – Perfect for high-volume food processing and bulk production.

- Tilting Mechanism – Effortless pouring and convenient cleaning for improved productivity.

- Heavy-Duty Motor – Ensures consistent performance even under continuous use.

- Strong Stainless Steel Body & Jar – Built for strength, hygiene, and long service life.

- Multi-Purpose Performance – Suitable for wet grinding, dry grinding, blending, and mixing.

- User-Friendly Controls – Easy operation with minimal supervision.

- Stable Base Design – Reduces vibrations and ensures safe, steady operation.

Ideal Applications

- Restaurants & Hotels

- Catering Units

- Industrial Kitchens

- Food Processing Plants

- Canteens & Mess Kitchens

- Sweet Shops & Bakeries

Why Choose the Platinum Flour Mill 14 Liter Mixer Grinder (Tilting Model)?

The Platinum Flour Mill 14 Liter Mixer Grinder Tilting Model is a perfect combination of power, convenience, and capacity, making it a top choice for professionals who need fast and consistent results in bulk food preparation.

Its tilt-and-pour mechanism, robust stainless steel build, and heavy-duty motor ensure easy operation, high performance, and durability — even during continuous use. Designed for modern commercial kitchens, this tilting mixer grinder enhances efficiency, hygiene, and productivity every day.

-

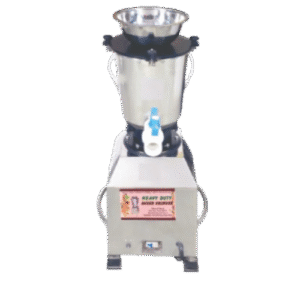

14 Liter Mixer Grinder Round Model

The Platinum Flour Mill 14 Liter Mixer Grinder Round Model is a powerful and efficient commercial-grade appliance built to handle large-scale grinding and mixing operations with ease. Designed for restaurants, hotels, canteens, food industries, and catering kitchens, this machine ensures consistent, fast, and smooth processing even for tough ingredients.

Equipped with a robust motor and a 14 Liter stainless steel jar, this Mixer Grinder can effortlessly grind, mix, or blend large batches of spices, pastes, chutneys, and batters. Its round, sturdy design provides excellent stability during operation, while its stainless steel body and jar ensure durability, hygiene, and long-lasting performance.

This model is ideal for professionals who need power, capacity, and reliability in one machine — making it a must-have for high-output commercial kitchens.

Key Features

- 14 Liter High-Capacity Jar – Perfect for large-scale food preparation.

- Heavy-Duty Industrial Motor – Delivers high torque for smooth and efficient grinding.

- Full Stainless Steel Construction – Rust-proof, durable, and easy to maintain.

- Round & Stable Design – Provides excellent balance and space-saving structure.

- Multi-Functional Use – Ideal for wet and dry grinding, mixing, and blending.

- User-Friendly Controls – Simple and safe operation for busy kitchen environments.

- Easy Cleaning & Maintenance – Designed for quick disassembly and effortless hygiene.

Ideal Applications

- Large Restaurants & Hotels

- Food Manufacturing Units

- Catering & Banquet Kitchens

- Commercial Canteens & Cafeterias

- Industrial & Institutional Kitchens

Why Choose the Platinum Flour Mill 14 Liter Mixer Grinder (Round Model)?

The Platinum Flour Mill 14 LTR Mixer Grinder Round Model is a powerhouse machine built for professional kitchens that require speed, strength, and reliability. With its high-capacity stainless steel jar, powerful 5HP motor, and sturdy design, it delivers smooth, efficient, and consistent grinding results for all types of food preparations.

Whether you’re making gravies, chutneys, or batters in bulk, this Mixer Grinder ensures flawless texture, long-lasting durability, and superior efficiency — making it an indispensable tool for every high-performance commercial kitchen.

-

14 Liter Mixer Grinder Square Model

The Platinum Flour Mill 14 Liter Mixer Grinder Square Model is a high-capacity, powerful, and durable commercial machine designed to meet the demanding needs of restaurants, hotels, industrial kitchens, and catering units. With its robust construction and heavy-duty motor, this machine ensures smooth, fast, and efficient mixing and grinding of both wet and dry ingredients in large quantities.

The square-shaped body offers excellent balance and stability, while the stainless steel jar and housing provide durability, hygiene, and easy maintenance. Whether you’re preparing gravies, chutneys, batters, or spice pastes, this Mixer Grinder delivers consistent performance and saves valuable preparation time in busy kitchens.

Key Features

- 14 Liter Stainless Steel Jar – Designed for bulk food preparation in commercial environments.

- Square Body Design – Provides superior stability, prevents vibrations, and ensures safe operation.

- Heavy-Duty Motor – Built for continuous use and capable of handling thick mixtures with ease.

- Durable Stainless Steel Construction – Ensures long life, hygiene, and corrosion resistance.

- Efficient Performance – Offers smooth and uniform grinding results for wet and dry ingredients.

- User-Friendly Design – Simple controls, easy operation, and quick cleaning.

- Noise & Vibration Reduction – Square model base helps minimize operational noise.

Ideal Applications

- Restaurants & Hotels

- Large-Scale Catering Units

- Industrial Kitchens

- Food Processing Facilities

- Sweet Shops & Bakeries

- Commercial Kitchens & Mess Halls

Why Choose the Platinum Flour Mill 14 Liter Mixer Grinder (Square Model)?

The Platinum Flour Mill 14 Liter Mixer Grinder Square Model is a top-performing machine built to handle heavy-duty commercial grinding tasks with precision and speed. Its large capacity, sturdy design, and powerful motor make it an ideal choice for professionals who need reliable, consistent results.

Designed for daily commercial use, this Gravy and Mixer Grinder ensures smooth texture, faster processing, and long-lasting durability, helping you improve productivity while maintaining top-quality food preparation standards.

-

15 HP Impact Pulverizer

The Platinum Flour Mill 15 HP Impact Pulverizer is a powerful, high-performance machine designed for efficient grinding and pulverization of various materials. Perfect for spice processing, food production, chemical, and pharmaceutical industries, this pulverizer ensures consistent, fine, and uniform output for large-scale production.

Equipped with a robust 15 HP motor and a precision impact grinding mechanism, this machine can easily handle hard, tough, and fibrous raw materials. Its sturdy construction and industrial-grade design make it suitable for continuous, heavy-duty operations, providing reliability and long-term durability in demanding work environments.

Key Features

- 15 HP High-Power Motor – Delivers exceptional performance for heavy-duty grinding tasks.

- Impact Pulverization Mechanism – Ensures fine, uniform, and high-quality powder output.

- Durable Industrial Construction – Built from premium materials to withstand continuous operation.

- Food-Grade & Hygienic Design – Suitable for spices, grains, and other edible materials.

- Versatile Applications – Ideal for grinding spices, grains, chemicals, and raw materials.

- Stable & Safe Operation – Reduces vibration and ensures secure, steady performance.

Ideal Applications

- Spice Grinding & Powder Production

- Grain & Seed Processing

- Pharmaceutical & Chemical Industries

- Food Processing Units

- Industrial Raw Material Pulverization

Why Choose the Platinum Flour Mill 15 HP Impact Pulverizer?

The Platinum Flour Mill 15 HP Impact Pulverizer is built for professionals who require high efficiency, precision, and reliability in their grinding operations. Its robust motor, impact-based grinding mechanism, and industrial-grade construction ensure smooth and consistent output, making it an essential tool for large-scale commercial and industrial applications.

Whether producing fine spice powders, processed grains, or chemical materials, this pulverizer guarantees high-quality output, increased productivity, and long-term durability, making it a valuable investment for any industrial processing unit.